Importance of Packaging in Logistics: Key to Business Success

Although often underestimated, packaging is an important element in achieving efficient logistics operations. Proper packaging is not just designed to protect products, but must be efficient for their transportation, storage and distribution.

Choosing the right materials and types of packaging helps to optimize processes and reduce costs, which is essential for small and medium-sized businesses that need to grow in a competitive market.

In this article we explore what packaging is in logistics, the advantages it offers and how it can impact the management of your logistics processes.

What is packaging in logistics?

In general terms, packaging is the set of elements and techniques used to contain products during transport, distribution and storage processes, so that they are protected and easier to move.

It is not just a physical layer of protection, but a comprehensive solution that ensures products arrive at their destination safely and efficiently.

When we talk about packaging in logistics, we are referring to the means that allow products to be secured from the moment they leave the factory until they reach the shelves.

Packaging may include boxes, pallets, bags, wrappers, among others, and must be designed according to the characteristics of each product, the transport conditions and the storage requirements.

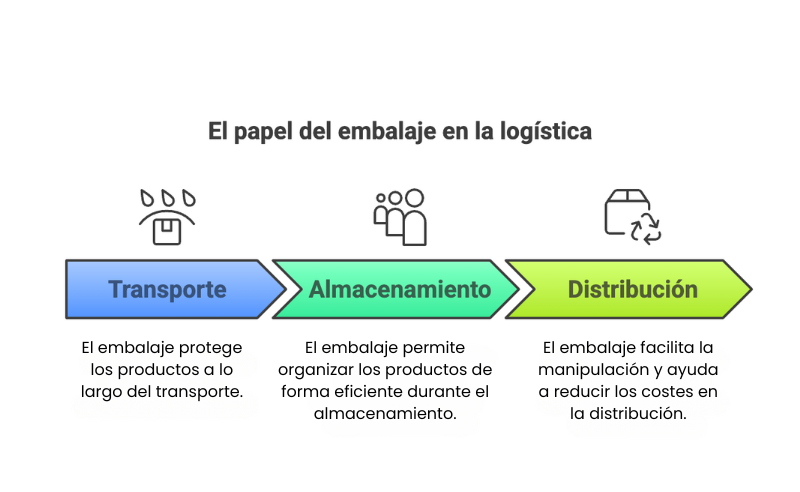

At every stage of the logistics process, packaging plays a fundamental role:

- Transport: Protects products so that they arrive intact at their final destination.

- Storage: Allows for efficient organization, making the most of the available space.

- Distribution: Facilitates product handling, reducing operating times and costs.

Advantages of good packaging for a company’s logistics

Appropriate packaging provides various strategic advantages, helping to optimize companies’ logistics processes:

Ensures safe transportation

Appropriate packaging is essential to ensure that products reach the end customer in perfect condition, even after undergoing long transport processes and facing adverse conditions.

The correct material and shape can protect products from factors that may be present both in means of transport and in storage spaces, such as physical impacts, humidity or extreme temperatures.

By reducing the risk of damage during transport, businesses minimise financial losses resulting from returns, claims or damaged products. All of this contributes to improved customer confidence and satisfaction.

Facilitates the handling of merchandise

Well-designed packaging is essential for moving goods efficiently. By adapting to the characteristics of each product, it facilitates loading, unloading and transfer tasks, allowing workers to handle products more quickly and safely.

Furthermore, by using the right materials, it is possible to reduce the weight and volume of packaged loads, optimising the use of space in warehouses and transport vehicles and helping to reduce operating costs.

Transmits the brand image

In addition to serving a practical purpose, packaging plays an important role in strengthening the brand image. Custom packaging can become a powerful marketing tool.

Innovative colours, logos, messages and materials can reinforce a company’s identity and convey its values to consumers.

For example, eco-friendly packaging, such as kraft drums, reflects a commitment to sustainability, while a premium design can highlight the quality of the product, leaving a lasting impression on the customer.

Product Identification

The incorporation of clear labels, barcodes or QR codes as part of an organized identification system allows for efficient and accurate traceability throughout the logistics process.

This enables real-time tracking of products, optimizes inventory and distribution processes, and reduces the risk of management errors. Additionally, it allows merchandise to be located more quickly and accurately, facilitating work in warehouses and distribution centers.

Makes storage easier

Packaging also has a direct impact on storage efficiency. Stackable or modular packaging allows for better organisation, optimising the use of available storage space.

In addition, the proper design of the packaged parts makes it easier to locate products, reducing search times and increasing the speed of logistics processes.

This is relevant in companies that move a large volume of products, where good organization of space can make a difference in operational efficiency.

Conclusion

Packaging plays a crucial role in the logistics of any company, especially for SMEs looking to optimize their processes and reduce costs.

From ensuring product safety during transport to improving efficiency in storage and distribution, good packaging has a direct impact on the operational process.

In addition, it reinforces the brand image and facilitates product traceability. Investing in efficient packaging solutions is a strategic decision that optimizes logistical resources, contributing to the growth of your business.

Frequently Asked Questions

What materials are recommended for effective packaging? Materials such as cardboard, plastic, foam and wood are common. The choice depends on the type of product, its fragility and the transport conditions.

What role does packaging play in sustainability? Sustainable packaging reduces environmental impact by using recyclable and biodegradable materials, which is increasingly valued by consumers and improves the company’s image.

Is it necessary to customize packaging for different products? Yes, customizing packaging based on product characteristics ensures better protection and presentation, which can result in a more satisfying customer experience.

How can the effectiveness of packaging in logistics be measured? Effectiveness can be measured through indicators such as the rate of damage during transport, customer satisfaction and the total cost of packaging in relation to the benefits obtained.

You may also like: